From Photovoltaic Solar Cells To The Main Types Of Solar Panels (Guide To Choosing The Convenable Solar Panel Type)

This article explains step by step, how a photovoltaic solar cell works, with an explanation of the different technical terms in a simple way.

It explains the different types of photovoltaic solar cells and solar panels, and at the end, makes a comparison between the types of solar modules in order to be able to choose the convenable solar panel type.

HOW DO SOLAR CELLS WORK? HERE IS A STEP-BY-STEP EXPLANATION

What is a solar cell?

Photovoltaics is the transformation of sunlight into electrical energy using photovoltaic solar cells.

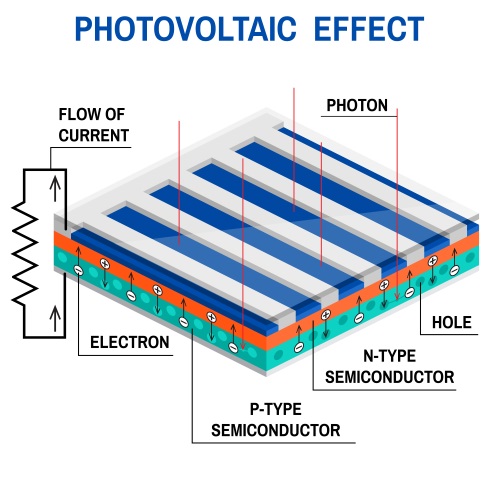

A photovoltaic solar cell is an electrical device within a solar module responsible for the converting of sunlight into electricity by a phenomenon called photovoltaic effect.

What is the photovoltaic effect?

The effect due to which light energy is converted to electric energy in certain semiconductor materials. The photovoltaic effect is noise-free and emission-free, it is one of the most environmentally friendly methods for power generation. For more information about the advantages of Photovoltaics see this article.

In the following paragraphs, we will explain step by step how a photovoltaic solar cell can use the photovoltaic effect to generate electricity.

What exactly is the task of a photovoltaic solar cell?

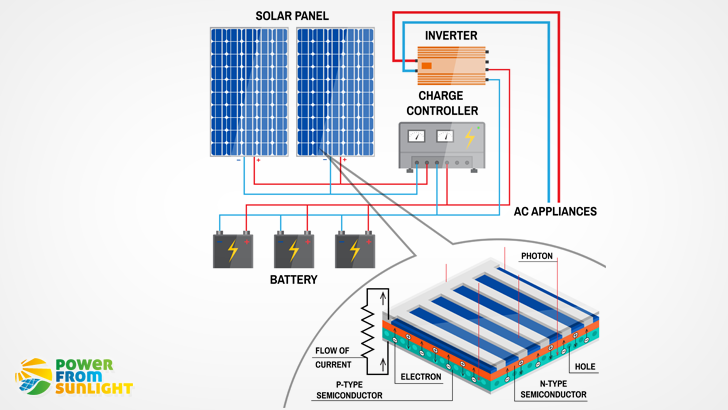

A photovoltaic solar cell uses the sunlight for charge separation in order to obtain electricity, for this process, a zone called space charge region is required, in which incident light particles called photons can strike on the charges to be separated.

How to create the necessary space charge region?

To generate this zone, you need two superposed opposite charged layers. These are obtained by using a substance called semiconductor (usually silicon is used).

What is a semiconductor?

A semiconductor is a material, which its electrical characteristics can be influenced by the admixing to foreign matters, this admixing is called doping.

Silicon doping and the construction of the space charge region

The doping takes place in two different layers of silicon:

- The final layer called n-layer is so doped to form there a surplus of electrons.

- The under-layer called p-layer is so doped to form there a deficit of electrons.

A contact between the two layers leads to the construction of an intermediate layer, the space charge region. In the space charge region between the two layers, the charges hold on to each other.

Now, the photovoltaic solar cell is created.

What happens when the sun shines on the solar cell?

In a photovoltaic solar cell, the final layer is so thin that the photons penetrate trough the space charge region, in which they give their energy up to electrons.

The excited electrons are free to move, follow the internal electrical field and exit the space charge zone onto the final layer of the photovoltaic solar cell.

How to use the energy of electrons to generate electricity?

To be able to use this energy, the photovoltaic solar cell is closed with the aid of contacts to a load: electrons flow via the load to the rear-side contact of the photovoltaic solar cell and electricity is generated.

How to produce more electricity with the photovoltaic effect?

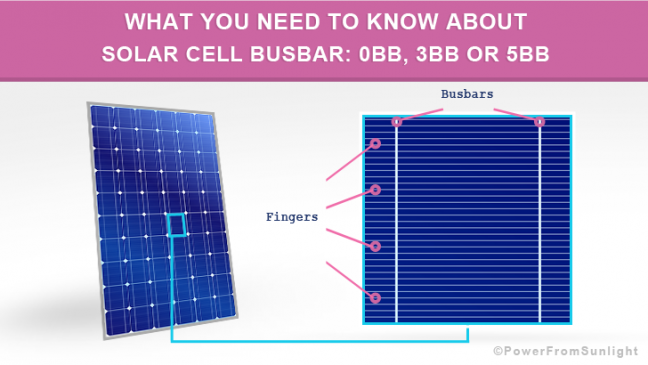

In order to generate more electricity by the photovoltaic effect, the individual photovoltaic solar cells are interconnected to form solar modules, which produce more direct current.

This current can be converted with the aid of solar power inverter into the standard network alternating current, now it can be stored or used for own consumption.

To know more about the solar inverter see this article.

WHAT ARE THE THREE PRIMARY TYPES OF SOLAR CELLS?

In this paragraph, we focus on the types of photovoltaic solar cells and the difference between them.

Photovoltaic solar cells are to be subdivided into three categories:

- Monocrystalline solar cells

- Polycrystalline solar cells and

- Thin film solar cells.

Crystalline solar cells are made of crystalline silicon. In the natural world, silicon is not found in its pure form, but in the form of silicon dioxide (sand).

For industrial use as semiconductor, the raw material quartz sand must be freed from any impurities and converted into so-called metallurgical silicon, which has a crystal structure.

Silicon for photovoltaic solar cells even has higher purity than the silicon for the production of computer chips.

Crystalline solar cells can be distinguished depending on the methods of manufacturing employed and the crystal arrangement of monocrystalline and polycrystalline solar cells.

Monocrystalline solar cells

The monocrystalline solar cells were already used for space applications. They go from dark blue to black and show an efficiency of between 16 to 20%.

The production method of this cells is very energy intensive. Therefore, the solar modules of this type are more expensive than of the polycrystalline solar cells.

Polycrystalline solar cells

More than 50% of installed solar modules are composed of polycrystalline solar cells. The level of efficiency is two percent less than that of the monocrystalline solar cells.

Because of that, the production is more energy-saving, and the modules from this type are cheaper than from the first type. Polycrystalline solar cells have a glittering blue appearance.

Thin film solar cells

Amorphous silicon or other coating materials such as cadmium telluride (CdTe) or copper indium gallium selenide (CIGS) are deposited in a thin layer onto the substrate material (e.g. glass). The thickness of the layers is less than 1 µm.

The thin film solar cells are thinner- by a factor of about a thousand – in contrast to the conventional crystalline solar cells.

Because less material is used, and no individual cells are produced, but complete thin film modules, the thin film solar technology is much cheaper than that of the crystalline.

To manufacture flexible solar modules, a synthetic material or thin stainless steel foil as the substrate material is supported.

There are three main types of thin-film solar cells, depending on the type of semiconductor used:

- amorphous silicon (a-Si),

- cadmium telluride (CdTe) and

- copper indium gallium deselenide (CIGS).

The efficiency of CIGS solar cell is approximately 14%, CdTe solar cell currently achieves the efficiency of 12.5 %. Amorphous silicon solar cell shows relatively low efficiencies of 6 to 8%.

Flexible thin film solar cells usually have a lower efficiency than the other thin-film solar cells.

However, the further development of this technology is busy researching, that an increasing efficiency is to be expected in the future.

Amorphous silicon solar cells are more commercially used than the other thin film solar cells, mainly in small applications such as backpacks, tents and outdoor clothing, in whose fibers amorphous silicon cells or current-generating roofing membranes have been incorporated and also in Building-integrated photovoltaics.

The use of thin-film solar cells leads to a marked reduction in prices of solar PV systems in the long term. Their percentage of the total module market increased over proportionately over the last few years.

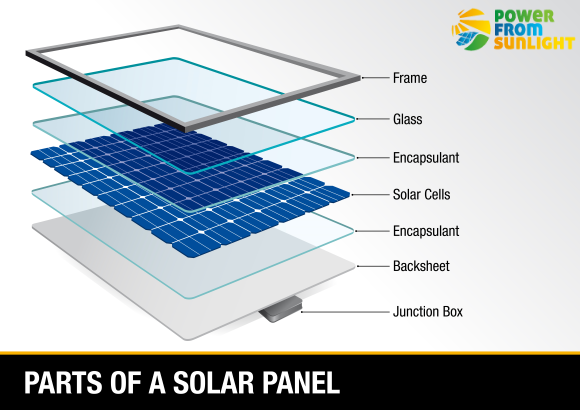

A photovoltaic solar cell alone is still far from being a solar module. In a solar module, many solar cells are electrically interconnected. They are embedded between glass or plastic sheets so that they will be protected from the wind and weather.

WHAT IS THE BEST TYPE OF SOLAR PANEL MONOCRYSTALLINE, POLYCRYSTALLINE OR THIN-FILM?

Just as with photovoltaic solar cells, there are three primary types of solar panels: monocrystalline, polycrystalline, and thin-film solar panels.

Monocrystalline solar panels

Due to its complicated production, modules from monocrystalline solar cells are more expensive and heavier than the other types of solar panels, but also the most efficient.

Another disadvantage of these modules is that they lose in their output at high temperatures or not optimal solar radiation. Therefore, they are especially suitable for small roof areas, which are southern oriented.

Polycrystalline solar panels

The production of these panels is less complicated than the monocrystalline but more complex than the thin film solar panels.

In contrast to monocrystalline rivals, polycrystalline solar panels have a lower efficiency

Just as with monocrystalline, they lose in their output at high temperatures or not optimal solar radiation.

Polycrystalline modules are less expensive than monocrystalline solar panels und are especially suitable for large or relatively small roof areas.

Thin layer modules – less efficient but they have low losses under poor light conditions and at high temperatures

In contrast to crystalline modules, Thin layer modules are very light and cheap, but they only have a low-efficiency rate. Worthwhile are thin-layer modules for very large roof areas and large plants, in which many solar panels can be mounted.

Unlike monocrystalline and polycrystalline modules, the output of thin layer modules increases slightly under poor light conditions and at high temperatures.

THE MOST IMPORTANT DIFFERENCE BETWEEN THE THREE TYPES OF SOLAR PANELS:

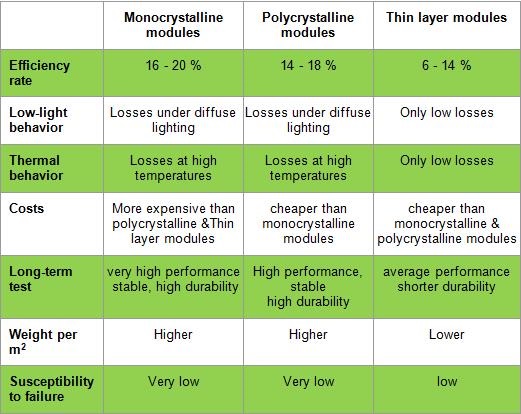

The following table summarizes the most important differences between the three types of solar panels: